Is Lean Right for My Company?

The answer is absolutely and Hell no! Let me go in to detail as to why it’s both. Lean manufacturing has a history spanning back over 100 years informally and formally since Toyota in the 1960s. It’s grown to other industries and goes by names like Lean Healthcare, Lean Government, Lean for Offices, Lean for Services, Lean IT, Lean for Financial Industry, Lean Startup, Agile, etc. In all its forms Lean is used as a way to deliver better service/products to the customer and reduce inefficiencies. At least what most would consider Lean. I want to introduce another framing and that Lean is designed to be competitive in your market.

When Toyota first started down the path of Lean they were facing a tough challenge. It was post World War II and the American companies had a large lead in the global market place on everyone else. On top of that the business was largely viewed as a commoditized business where the best way to compete was to lower costs. Lowering costs was done by selling in high volumes and leveraging economies of scale. So if you are a cash strapped company and don’t have the money to buy in bulk what do you do? If you are Toyota you look for ways to remove waste from the process and remove hidden costs. That’s where we get the seven wastes (Muda) (Transportation Inventory Motion Waiting Over-production Over-processing Defects – TIM WOOD). These seven wastes are the corner stone of what most people learn about when they learn Lean. If you have a good Lean leader they will also teach about the other ways to find hidden costs like Flow (Mura) and Overburdening (Muri). All of which are designed to give a company more cash flow to grow a business.

If you are using Lean as a way to just control costs then you will get benefits in the short run but it may not last. Lean is a Growth Strategy and doesn’t work over the long run if it’s not treated like a growth strategy. If you hope to get the long term benefits of lean it has to be a growth strategy. Many of the ways Lean gets implemented in a company is with the help of the people doing the work. If you use Lean as a cost cutting strategy then what ends up happening is that the very people that helped you get the gains end up being cut. This is because you eventually run out of other opportunities like inventory reduction. If you are growing as a company and are adding new people, technology, or equipment then there is more room for improvement.

The 2nd best way to use Lean is as a growth strategy. The best way to use it is to use the principles to be competitive in your market. One of the best way examples is Lean Startup from the software world. In the Lean Startup model it doesn’t talk about the 7 wastes. Instead the focus is on iterations of software versions and creating MVPs (minimal viable products) and testing it. The faster you can do it relative to your market then the more of an advantage you will have. This is a concept called Boyd’s Law and for more information you can see other articles I’ve written on the topic.

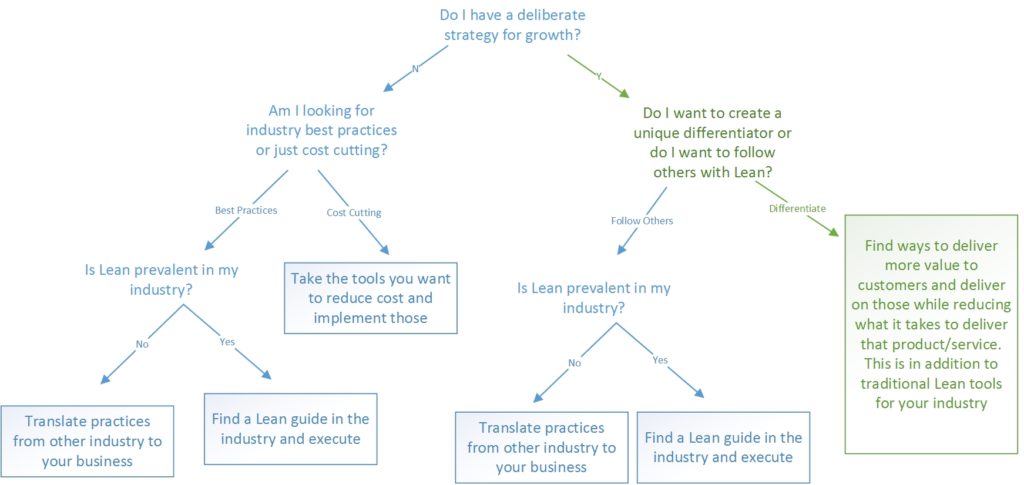

So the question may be not “Is Lean Right for My Company” but “What version/level of Lean is right for my company?” Here is a basic decision tree to help you with direction:

For more information on how to implement Lean into your business you can apply for a Discovery Call on how you can implement Lean in Your Business.