Kaizen and Kaikaku (Breakthrough Kaizen)

You may have heard of Kaizen which is incremental continuous improvement. It is a great way to make improvements consistently in any organization. The idea behind Kaizen is to just be a little better than before. Over time Kaizen can lead to significant changes.

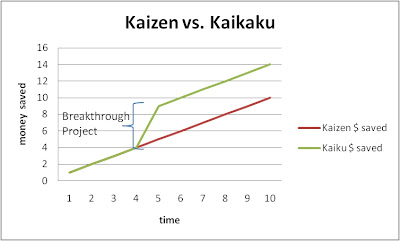

Another concept that doesn’t get talked about as much in a Lean Business System is Kaikaku. Kaikaku is a major breakthrough also known as breakthrough kaizen. What does that mean? Well a picture is worth a thousand words:

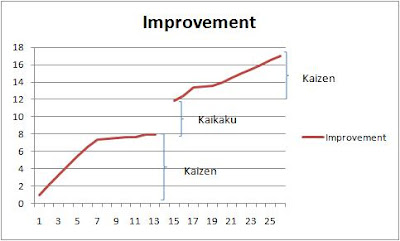

What tends to happen in reality is something more like this:

Kaizen improvements will take you so far then you need a breakthrough improvement (Kaikaku). Kaizen would be like a 5s program where Kaikaku would be a line design project that converts your entire front to back process from batch to single piece flow. Going from cell build to progressive build can also be an example of a Kaikau.

How do you know when to use Kaizen and when to use Kaikaku? I like to use these rules:

1) Define what success looks like for your operations. In manufacturing you might use delivery time, % of operation that is waste, or even defect rates. In the service industries you may use number of customers, wait times, or even employee turnover.

2) Do Kaizen activity until you start hitting a glass ceiling with your improvements. This is when you start seeing diminishing returns on your improvements.

3) Test your breakthrough idea thoroughly before large scale implementation with cardboard mock-ups and an iterative design process.

4) Continue to Kaizen the new design.

For more information or any other questions please contact us.