Lean in the Office

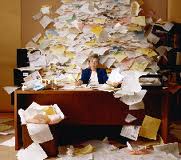

You might think of a scene like the one in the picture when you think of a “non-Lean office.” The fact is that Lean in the office is much more than just a 5s program. For those unfamiliar, 5s is a 5 step process to help organize the work space and more importantly you use 5s to help see where there might be opportunities for improvements. The 5s process is 1) Sort 2) Set 3) Shine 4) Standardize 5) Sustain. For more information please contact us.

A Lean office is an office that is designed to deliver the most value with minimal waste to a customer. 5s is a great place to start because it will usually lead to other findings which you can improve. We have found a slightly different way to approach a lean office. First step is to give everyone Lean training and teaching people to see what is value and what is waste. The next step is to look at what you are currently doing well and try to see how you can do more of it. An example of this is at an office I helped they were a a couple of people great at communicating with customers/clients. We decided to standardize as much as possible their process and train others on how to have good interactions with customers/clients. The training was done by the people who were thought to be the leaders in the area (a receptionist, a manger, and a technician). You can find what’s working well by doing an appreciative inquiry.

After leveraging what you have working well then there is an opportunity to work on the problem areas. We usually like to do some mapping events to get a good feel for where the main opportunities lay. A value stream map or multiple value stream maps is ideal for this step. In an office setting value stream maps can get a bit hairy and may not be as clear as in a manufacturing setting. Don’t worry that is ok just do the best you can in mapping. Once you’ve mapped out the current state for a particular area then design an ideal future state map. The difference from the current state and the ideal state will be the projects you will need to work on in your office. Don’t worry if you can’t get everything done this year, just prioritize and pick which ones you want to do. Just remember that this is iterative so if it’s not perfect then don’t worry you’ll have another change to improve it. We recommend doing a value stream map at least once a year and doing both a current state and future state map.

From this point you can go in several directions but you will have multiple projects to work on through out the year. For sustaining and continuous improvement we find that daily management helps. This is a simple board with metrics and if the metrics aren’t meet then we try to root cause the problem and solve it so it doesn’t happen again in the future. It’s a great way to engage all people and give them ownership in their work space. For more information on daily management, value stream mapping, or any other questions you may have please contact us.